Project Background:

• Hebei Pharmaceutical Co., Ltd.

Solutions:

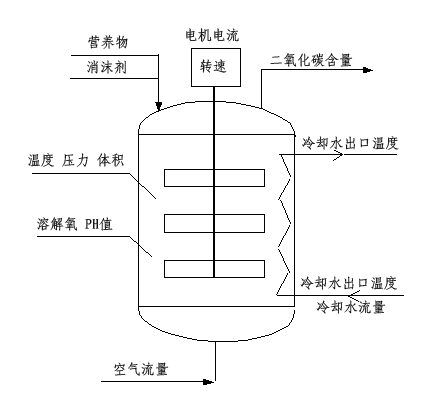

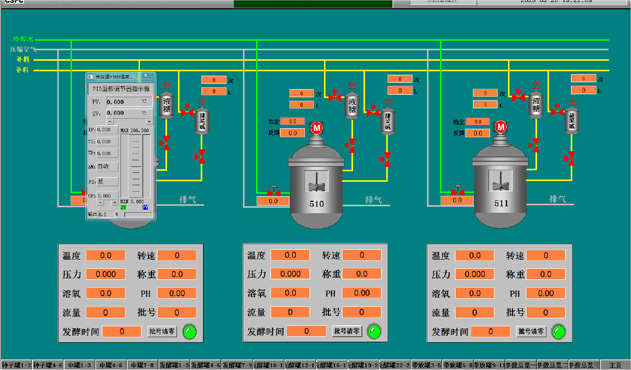

• Temperature control: The control of fermentation temperature during biofermentation is an important environmental parameter for microbial growth that must be strictly controlled. The main factors influencing the fermentation temperature are the temperature of microbial fermentation, motor mixing and cooling water. For small fermentation tank temperature control system is the fermentation tank temperature as a controlled parameter, A single circuit control scheme with cooling water flow as control parameters. For large fermentation tank systems, the main circuit is the temperature of the fermentation tank. A serial control or feedback-feedback control scheme using a cooling water system as a secondary circuit.

• Pressure control: Control by regulating the amount of gas discharged. The general use of single-loop control is possible, for the fermentation tank pressure changes on the effect of dissolved oxygen concentration, is treated by the dissolved oxygen concentration adjustment circuit, of course, the regulation of dissolved oxygen concentration will take into account the effect of pressure on the tank.

• PH value control: The pH value is controlled by controlling how much adjusting fluid is added.

• Dissolved oxygen concentration control: the main factors affecting the dissolved oxygen concentration are the amount of air supplied, the speed of the agitator and the pressure of the fermentation tank. In the case of constant agitator speed, the concentration of dissolved oxygen is controlled by adjusting the amount of air supplied. Of course, there is also an integrated regulation of the speed of the fermentation tank and the amount of air supplied.

• Defoaming control: defoaming control usually adopts a double-position control method, when the fermentation liquid reaches a certain height, automatically open the defoaming agent valve, when the liquid is dropped back to normal, automatically close the defoaming agent valve.

• Recharge control: Control the rate of recharge based on the release rate of carbon dioxide from the exporting gas, adjust the amount of recharge with the equilibrium of chemical elements, control the recharge with the method of respirator.

Monitoring parameters for fermentation tanks

Project Highlights:

• Fermentation levels of 200-230mg/L, 25% higher efficiency, 12% lower production costs and 83.5% yield.

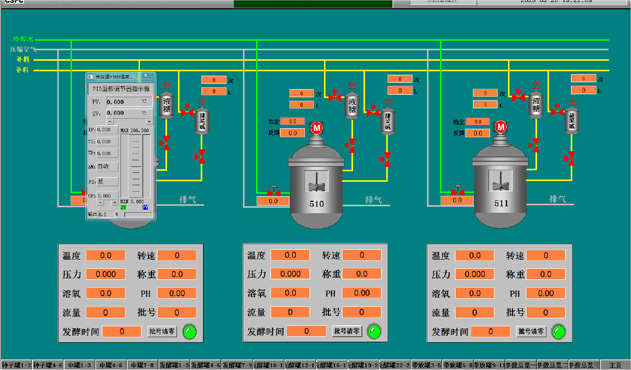

fermenter

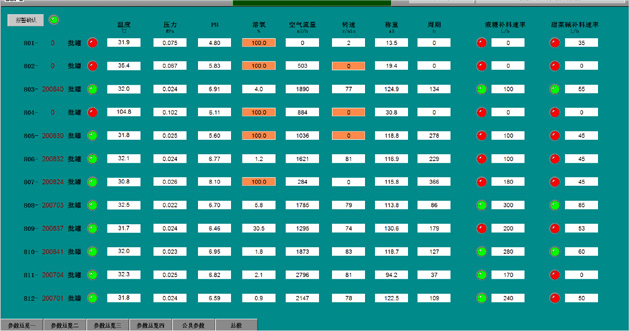

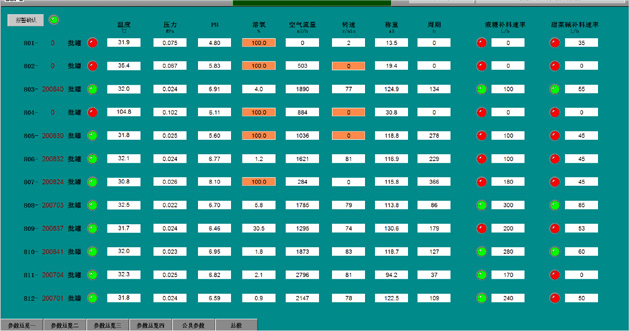

Overview of Parameters

Project Background:

• Hebei Pharmaceutical Co., Ltd.

Solutions:

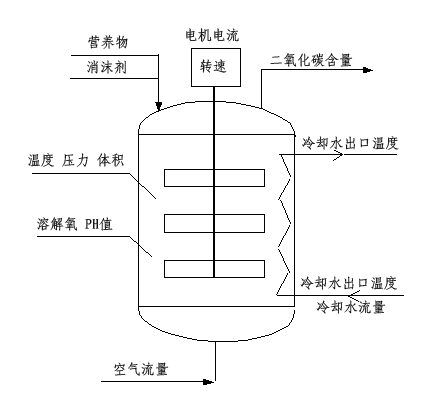

• Temperature control: The control of fermentation temperature during biofermentation is an important environmental parameter for microbial growth that must be strictly controlled. The main factors influencing the fermentation temperature are the temperature of microbial fermentation, motor mixing and cooling water. For small fermentation tank temperature control system is the fermentation tank temperature as a controlled parameter, A single circuit control scheme with cooling water flow as control parameters. For large fermentation tank systems, the main circuit is the temperature of the fermentation tank. A serial control or feedback-feedback control scheme using a cooling water system as a secondary circuit.

• Pressure control: Control by regulating the amount of gas discharged. The general use of single-loop control is possible, for the fermentation tank pressure changes on the effect of dissolved oxygen concentration, is treated by the dissolved oxygen concentration adjustment circuit, of course, the regulation of dissolved oxygen concentration will take into account the effect of pressure on the tank.

• PH value control: The pH value is controlled by controlling how much adjusting fluid is added.

• Dissolved oxygen concentration control: the main factors affecting the dissolved oxygen concentration are the amount of air supplied, the speed of the agitator and the pressure of the fermentation tank. In the case of constant agitator speed, the concentration of dissolved oxygen is controlled by adjusting the amount of air supplied. Of course, there is also an integrated regulation of the speed of the fermentation tank and the amount of air supplied.

• Defoaming control: defoaming control usually adopts a double-position control method, when the fermentation liquid reaches a certain height, automatically open the defoaming agent valve, when the liquid is dropped back to normal, automatically close the defoaming agent valve.

• Recharge control: Control the rate of recharge based on the release rate of carbon dioxide from the exporting gas, adjust the amount of recharge with the equilibrium of chemical elements, control the recharge with the method of respirator.

Monitoring parameters for fermentation tanks

Project Highlights:

• Fermentation levels of 200-230mg/L, 25% higher efficiency, 12% lower production costs and 83.5% yield.

fermenter

Overview of Parameters